Microwave Heating

RF Microwave Heating: Benefits and Applications Across Industries

RF microwave heating offers unique advantages due to the ability to generate continuous-wave microwave energy, enabling rapid and selective heating. This makes RF microwave tempering ideal for various industrial applications. Let's explore the benefits and applications:

1. Food Processing

- Food Preparation and Preservation:

- Thawing (frozen meats)

- Cooking (bacon)

- Pre-cooking (snacks, meals)

- Sterilization & Pasteurization

- Drying (bakery products, raw foodstuffs)

2. Industrial Material Processing

- Drying & Curing:

- Various materials (carbon black, clay, ceramics, wood, desiccants, filter materials, sand casting molds)

- Composites (carbon fiber, fiberglass)

- Particle board & veneers

- Chemical & Thermal Processing:

- Polymer processing

- Metal powder sintering

- Rubber vulcanization

3. Advanced & Exotic Material Processing

- Material Synthesis & Conversion:

- CVD diamond production

- Gas reforming (hydrogen, ammonia)

- Waste pyrolysis (biofuels, chemicals)

- Semiconductor Manufacturing:

- Annealing, doping, etc.

4. Mining & Mineral Processing

- Ore Beneficiation:

- Selective ore fracturing

Benefits of RF Microwave using L-Band CW Magnetron Tubes:

- Rapid & Selective Heating: Precise control, reduced energy consumption

- Improved Efficiency: Faster processing, increased productivity

- Enhanced Product Quality: Uniform heating, reduced defects

- Reduced Environmental Impact: Lower energy, less waste

- Versatility: Wide range of applications

Machlett Microwave High Voltage Transformer

In Stock

— Just a few left

CWM-100 100 kW L-Band CW Magnetron Tube

In Stock

— Just a few left

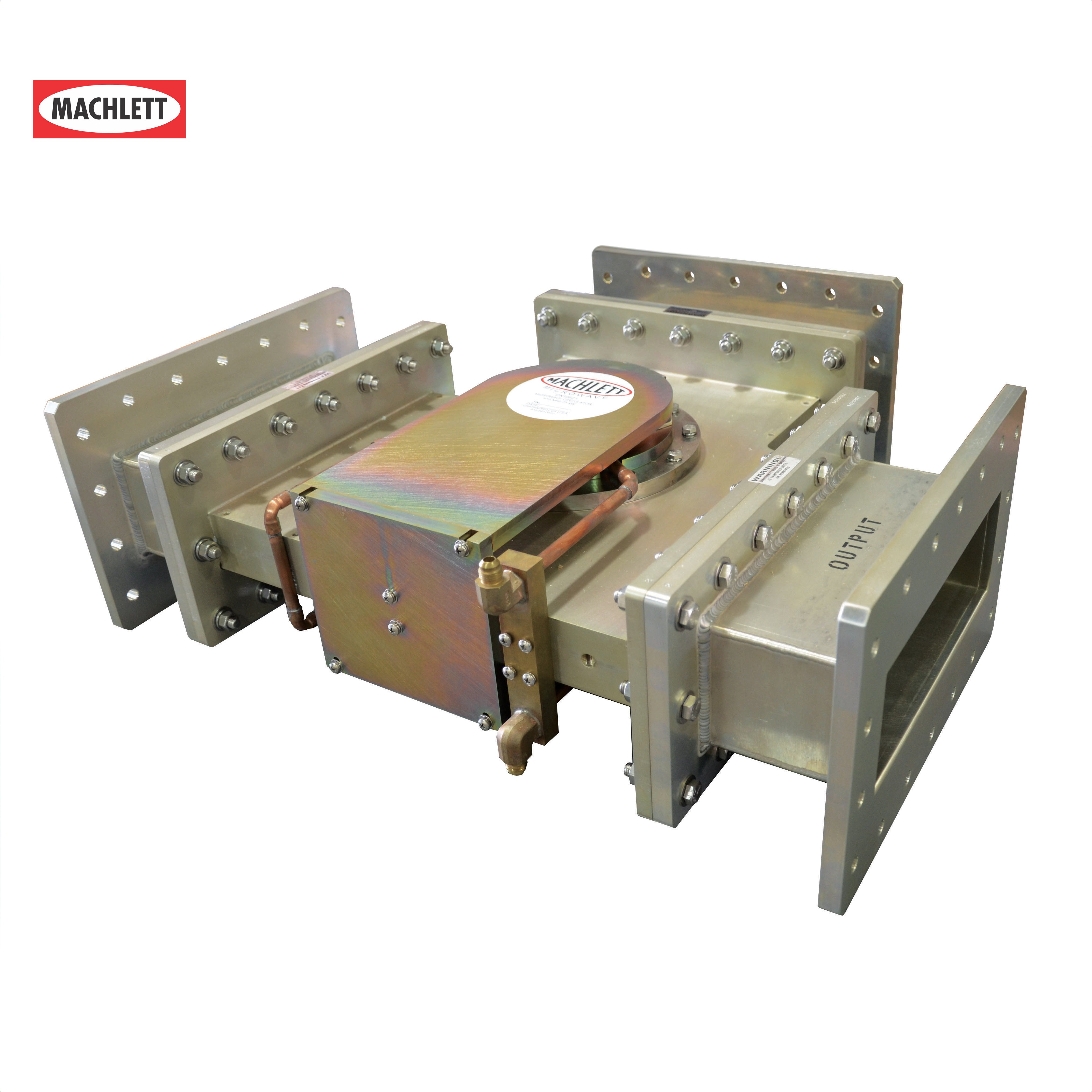

Waveguide Circulator - 915 MHz, 75 kW, UHF Band

In Stock

— Just a few left

CWM-75kW L-Band CW Magnetron Tube

In Stock

— Just a few left

Get in Touch with us

Be the First to Know. Sign up to newsletter today.